What is Cobalt-60?

Cobalt-60 is an isotope that emits gamma rays essential to the medical community for cancer treatments, as well as sterilization of medical devices.

Sterilization Cobalt-60

Sterilization Cobalt-60 is the first and most widely used type of Cobalt-60. It is employed by the healthcare industry to sterilize medical devices such as sutures, gloves and syringes. This type of Cobalt-60 is typically sourced from nuclear companies like Bruce Power in great quantities. In fact, LSA Cobalt-60 sterilizes more than 40 per cent of the world’s single-use medical devices.

Medical-grade Cobalt-60

Medical-grade Cobalt-60 is used worldwide to battle cancer and for radiation therapy for the treatment of complex brain conditions. Bruce Power has recently begun producing this new source of Cobalt, which will ensure doctors and their patients have treatments when they need them, and access to new and innovative machines.

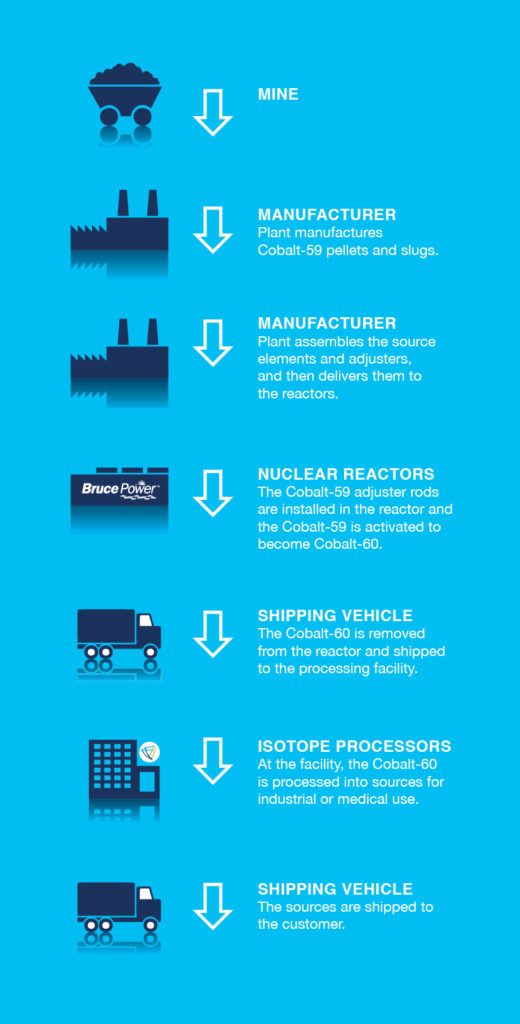

What is Bruce Power’s role in its creation?

For more than 30 years, the four reactors at Bruce Power’s Bruce B generating station have been a reliable Cobalt-60 supply for Nordion, an Ottawa-based company.

The Cobalt-60 rods are stored in Bruce Power’s secondary fuel bay. The harvested rods are suspended on the wall of the fuel bay, about 14 feet below the surface; the water providing employees with shielding from the radioactivity. From the reactivity mechanism deck over the fuel bay, Bruce Power’s specialized fuel handlers extract the individual irradiated rods and place them in a shielded flask to be shipped to Nordion’s facility.

What can be done with Cobalt?

Sterilization

Gamma sterilization is a proven process that’s highly effective at treating single-use medical devices. With the ability to penetrate products while sealed in its final packaging, gamma sterilization economizes the manufacturing and distribution process, while still ensuring full sterility of the product.

Sterilization of Combination Devices

A combination device is a medical device combined with a tissue, pharmaceutical or other component that falls within one or more regulatory standards, such as drug-eluting stents. Sterilization can affect drug and material properties, so sterilization by gamma irradiation is applied to ensure that the combination device’s sterility and functionality are maintained.

Sterilization of Implantable Devices

Implantable devices include orthopedics (i.e. knees), stents, heart valves and more. Metal and polymers present a challenge to some sterilization modalities. Gamma is highly efficient for sterilization of implantable devices; in fact, the highest percentage of sterilization modalities for orthopedics is gamma. Additionally, many implantable devices are high value and therefore depend on a reliable process to ensure quality control and prevent the potential for lost product due to processing faults.

Sterilization of Pharmaceuticals

Sterilization by gamma irradiation is advantageous for a wide range of pharmaceutical products. Due to the high demand in the pharmaceutical industry, gamma has proven itself to be an effective method as indicated by its acceptance in the European Pharmacopeia, and, more recently, drafted into the United States Pharmacopeial Convention. Some of the advantages of gamma over other modalities include high penetration power, isothermal character (small temperature rise) and no residues. It also provides a better assurance of product sterility than aseptic processing and lower validation demands.

Gamma Knife and Cancer Treatment

One of the technological advancements is the Elekta Gamma Knife® surgery, which uses an innovative tool that allows for non-invasive treatment of brain disorders, which is complex to do through conventional means. Stereotactic Radiosurgery using Cobalt-60 therapy allows doctors to deliver higher doses of radiation to tumours, while limiting damage to the surrounding healthy tissue and organs. For many brain cancers, Cobalt-60 therapy is one of the most precise and advanced forms of radiation treatment available.

Gamma Knife radiosurgery is a type of radiation therapy used to treat tumours and other abnormalities in the brain. In Gamma Knife radiosurgery, specialized equipment focuses close to 200 tiny beams of radiation on a tumour or other target. Although each beam has very little effect on the healthy brain tissue it passes through, a strong dose of radiation is delivered to the site where all the beams meet.

The precision of Gamma Knife radiosurgery results in minimal damage to healthy tissues surrounding the target. In some cases, Gamma Knife radiosurgery may have a lower risk of side effects compared with other types of radiation therapy. Also, Gamma Knife radiosurgery is often a safer option than traditional brain surgery.

Gamma Knife radiosurgery is usually a one-time therapy, completed in a single day.

Another such way is Xcision’s GammaPod, which is a new solution that is designed to provide non-invasive treatments to patients, with the potential to shorten the course of radiotherapy and limit doses to the surrounding healthy tissue, including the whole breast, heart and lungs.

Insect Sterilization

Cobalt-60 is the key component of the Sterile Insect Technique (SIT), a process aimed at eliminating or, at a minimum, suppressing the population of insects that spread disease like Zika virus. In this case it’s like a high-tech form of insect birth control for mosquitoes.

The International Atomic Energy Association has deployed the SIT using gamma radiation from Cobalt-60 to combat the spread of Zika and West Nile viruses, as well as dengue. SIT poses no risk to the environment or to public health and, in fact, is considered one of the most environmentally friendly insect pest control methods ever developed because the insects are not self-replicating and do not become established in the environment.

Pioneered in the 1950s, SIT involves using gamma irradiation to render sterile insects such as male tse-tse flies, screw-worm flies and other fruit flies, especially in climates that stay warm year-round. After irradiation, large numbers of sterile males are released into the wild, dramatically reducing the number of insects in the next generation. Repeated release can eventually wipe out a population of insects.

Food Irradiation

Gamma is also used to disinfect certain food and consumer products such as spices and cosmetics, and eliminate invasive insect pests from tropical produce prior to export to various countries. While some methods leave traces of toxic substances, gamma rays do not. The rays are highly effective at killing micro-organisms and insect pests, yet there is no residue or radioactivity on or in the products and packaging. This means no quarantine is required, and product is immediately available for shipment or use after processing.

The American Spice Trade Association provides guidance on the use of irradiation as a microbial reduction strategy for spices. In some countries, regulatory requirements and consumer demands are restricting the use of chemical treatments required for export of fruits and vegetables. The growing awareness of the dangers of chemicals that are known carcinogens has led countries to review and, in some cases, suspend their use. These and other drivers have resulted in an increase in irradiation of food products as an alternative to chemical treatments.

Gamma irradiation is also used to treat meat and produce against micro-organisms such as E. coli and salmonella. Irradiation is for the safety of consumers and neither changes the taste nor the nutrient levels of the food.

Agriculture and R&D

Cobalt-60, which is produced in four of Bruce Power’s eight nuclear reactors, is used for the Sterile Insect Technique (SIT), which could be a powerful strategy for controlling the pepper weevil, a devastating pest problem for Ontario pepper farmers. Bruce Power and Nordion have both put forth funding and support for a multi-year study led by University of Guelph Professor Cynthia Scott-Dupree on sterilizing pepper weevils using Cobalt-60. The researchers hope to control pepper weevils, which can burrow into farmed peppers and destroy them from the inside.

It is very difficult to control these insects when they are hidden inside the pepper, and, in 2016, pepper weevils caused significant damage to the crop in both field and greenhouse production systems.

Gamma radiation from Cobalt-60 will sterilize the insects before they are released to mate normal, unsterilized pepper weevils in greenhouses. The only pepper weevils released will have all the attributes of normal, unsterilized weevils, except they are sterile. When they mate, the eggs will not be viable, no progeny results and the pest population will decrease.

This innovative research could improve Ontario’s agricultural sector by reducing the impact of pests on produce, while also providing a possible gateway to the future of farming.